Photo: © Kone

News | April 2024

Kone acquires Paca Ascenseurs

Assa Abloy has sold its lift maintenance business Paca ascenseur (Paca) in France to Kone. With this acquisition, Kone intends to strengthen its local presence in the region.

July 2016

The test tower of Thyssenkrupp Elevator in Rottweil provides two different things: a huge test laboratory for lifts and a breath-taking panorama view.

Laboratories appear rather sterile to outsiders. They are only fascinating to those who know their way around them. This is not the case with the test tower for lifts of Thyssenkrupp Elevator in Rottweil in the German state Baden-Württemberg. A viewing platform with glass facades approximately 4 m high provides a fantastic 360° view at 232 m – in ideal weather all the way to the Alps. The platform has now been opened in the presence of journalists in what is still the tower shell structure. It will also be accessible to the public in just under a year.

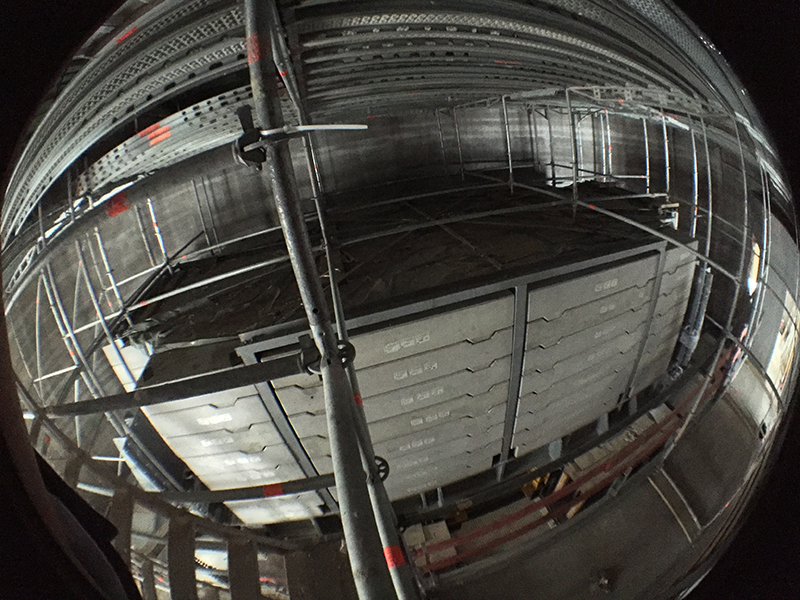

Research is to be conducted inside the tower from December. One of the large drives has already been prepared for installation in the Thyssenkrupp plant in Neuhausen near Stuttgart: the machine will in future move the fastest lift in the test tower at up to 18 m per second through the shaft. A similar drive is already in operation today in the One World Trade Center in New York and in the Shanghai World Financial Center. At the end of January a huge pendulum, kept in motion by electromagnetic linear motors, was installed by GERB Schwingungsisolierungen GmbH in the tower pipe – at a height of 193 m.

Research is to be conducted inside the tower from December. One of the large drives has already been prepared for installation in the Thyssenkrupp plant in Neuhausen near Stuttgart: the machine will in future move the fastest lift in the test tower at up to 18 m per second through the shaft. A similar drive is already in operation today in the One World Trade Center in New York and in the Shanghai World Financial Center. At the end of January a huge pendulum, kept in motion by electromagnetic linear motors, was installed by GERB Schwingungsisolierungen GmbH in the tower pipe – at a height of 193 m.

This technology has already been installed in high-rise buildings in New York, Shanghai or Dubai, but it is unique in its combination of active and passive movement, "Thanks to the active pendulum, the development engineers of Thyssenkrupp Elevator can test lift systems under realistic conditions,” reported the chairman of the board of directors of Thyssenkrupp Elevator, Andreas Schierenbeck.

"We can also simulate the oscillations of various buildings that actually exist.” The future technologies being tested in Rottweil in particular include the latest lift generation, the MULTI. Three of the twelve tower shafts in the new test installation are intended just for the new MULTI system.

The tower will be endowed with its final appearance in the summer: this will be an envelope made of a polymer-coated fibre glass fabric approximately 17,000 m2. This is on the one hand a highly complex material that is durable and self-cleaning. On the other hand it will protect the tower against intense sunshine and reduce the building’s own movement by reducing the force of the wind.

The tower will be endowed with its final appearance in the summer: this will be an envelope made of a polymer-coated fibre glass fabric approximately 17,000 m2. This is on the one hand a highly complex material that is durable and self-cleaning. On the other hand it will protect the tower against intense sunshine and reduce the building’s own movement by reducing the force of the wind.

The material was used at the football world championships in 2010 in South Africa: in the "Cape Town Stadium” the building was sheathed in an almost transparent membrane of fibre glass. Due to the phased transition of the envelope, the tower is almost opaque in the lower area and becomes more transparent towards the top, since the fabric becomes more wide-meshed.

The membrane also permits the extraordinary lighting concept of the test tower. Once it has been completed, the countless LEDs behind the membrane will allow the tower to shine. "As a result, the tower will become a lighthouse project for Thyssenkrupp,” according to Schierenbeck.

Bettina Heimsoeth

Write a comment