Chinese elevators are to be made safer

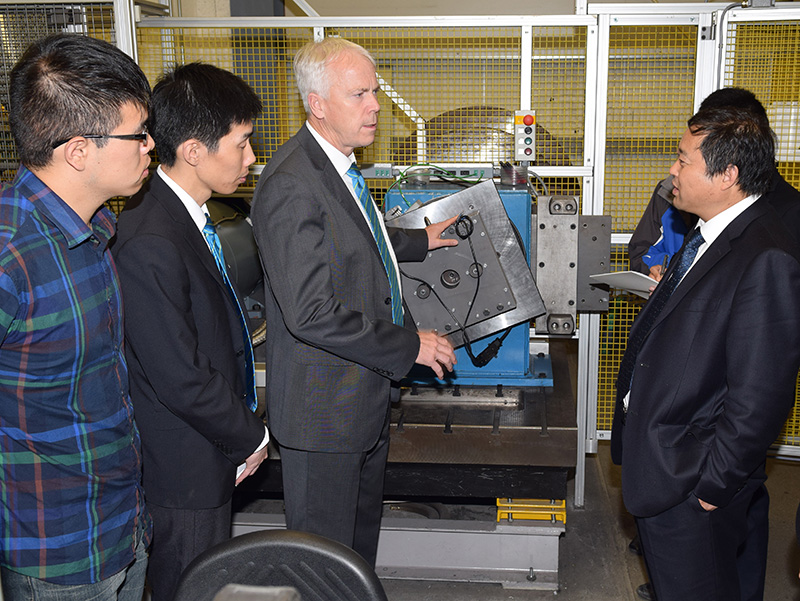

Elevator manufacturers in China are working hard on improving the safety of their elevator systems. This is the reason why, during the Interlift 2015, representatives of the leading Chinese elevator associations visited the German headquarters of Mayr power transmission, the leading manufacturer of elevator brakes worldwide.

The participants were able to see how Mayr achieves the quality and superb reliability of its products. In order to cover the demand for elevator brakes in China, which has been increasing for years, Mary will be constructing a new plant in the Middle Kingdom.

Safety at all times

Every year, approximately 12,000 elevators are newly installed in Germany. Most of these are equipped with safety brakes by Mayr power transmission, the global market leader for elevator brakes. In elevators, Mary brakes guarantee the safety of passengers at all times. In China, which has for years been viewed internationally as the most important manufacturing country and the largest sales market of the branch, a substantially higher number of elevators – approximately half a million – are installed per year.

And these should now become safer as well. At the Interlift 2015, representatives from different Chinese elevator associations obtained information on branch innovations and asked for insight into how Mayr ensures the quality and reliability of its products. During the trade fair, approximately 30 representatives of the Chinese elevator associations, amongst them the China Elevator Association (CEA) and the Shanghai Elevator Trade Association, as well as renowned elevator manufacturers from China also took the time to visit the German headquarters of Mayr power transmission in Mauerstetten.

100% quality controls

During the visit, several representatives made it clear that, in the past, they had neglected the subject of elevator brakes and had not sufficiently tested and qualified them, but had rather left this job to the drive manufacturers. In addition, prototype tests, during which elevators are tested once for their functionality, reveal nothing about the quality of large quantities. "Every individual brake must be supplied in the required quality. To achieve this, the appropriate testing routine is required”, says Johann Eberle, Marketing and Sales Manager at Mayr power transmission.

"The risk is often that manufacturers with little experience are not, so to speak, aware of what they don’t know. In order to guarantee the necessary safety standards permanently, clear processes, comprehensive testing possibilities, years of experience and highly-qualified employees represent essential prerequisites. This costs money, but only in this way can safety be achieved. In future, it will not be the cheapest provider, but rather the most reliable provider who will be winning market shares, also in China”.

Careful quality checks

The representatives of the Chinese associations were able to convince themselves on-site of the careful quality checks conducted on Mayr safety brakes: These include quality assurance measures during the design process as well as a comprehensive final test. Prior to delivery, all brakes are extensively tested on calibrated test stands and function-relevant values are documented. An electronic database in which the measurement values together with the associated serial numbers of a product are stored ensures 100 per cent traceability in the process.

As the global technology and market leader, Mayr power transmission plays a pioneering role. For example, the company is also one of the first manufacturers on the market to offer safety brakes based on the new elevator standards EN 81-20 and EN 81-50. Since the Interlift, Mayr power transmission has already been providing a prototype inspection certificate issued by the TÜV Süd (German Technical Inspectorate) acc. Directive 2014/33/EU for all affected elevator brakes, which is to become mandatory for all manufacturers as of 20 April 2016. In this way, the company is already providing customers with planning security.

A new plant in China

To ensure access to the Asian market, Mayr has already been operating their own plant in Zhangjiagang near Shanghai since 2004, currently with a staff of approximately 110 employees. "For our Chinese plant, the same quality standards apply as in Germany”, explains Jack Tang, Sales Manager at Mayr China, who had also travelled to the Interlift. "The company quality management system in Zhangjiagang is certified acc. ISO 9001, just as it is in Mauerstetten.

This confirms the quality consciousness of the employees at all levels of the company”. And there is a huge demand in China for high-quality, reliable elevator brakes: Mayr is currently constructing a new plant with almost 8,000 m2 production area directly adjacent to the existing subsidiary, in order to cover this high demand. The Chinese market has in the meantime also recognised that appropriate levels of production competence and maximum care are essential for the reliable transport of the passengers – as safety does not allow for compromises.

www.mayr.com

Write a comment