Photo: © privat

News | April 2024

Obituary for Gerhard Thumm

Gerhard Thumm died at the end of February 2024 at the age of 72. He held various responsible positions at TK Elevator from 1976 to 2018.

May 2016

At interlift exhibition the Munich component manufacturer Meiller Aufzugtüren GmbH unveiled its new Gravida threshold concept.

Apart from aluminium thresholds (for passenger and cargo lifts) and solid heavy duty thresholds (for heavy industrial lifts), Meiller has provided an alternative with this threshold system to the previously used profile and pipe segment thresholds made of steel or stainless steel in the medium and heavy load range.

The new Gravida threshold consists of three assemblies: the base plate (2 mm) and cover plate (3 mm) form the body of the threshold and are made of galvanised steel or stainless steel. The appearance of the cover plate of the PURA design threshold visible to the user has been adjusted by Meiller: the grooves in which the guides of the door leaves run have only been lasered out to the extent required for the travel of the door leaves.

Consequently no guide grooves are visible when the door is closed, which contributes to the aesthetic appearance of high quality passenger lifts in particular. The stainless steel plate is delivered as standard in ground design (240 K), but other surfaces are possible too. In addition, as in all Meiller standard thresholds, the width of the lasered guide groove is only 7 mm and as a result provides better protection against dirt, which can lead to blocking of the door leaves.

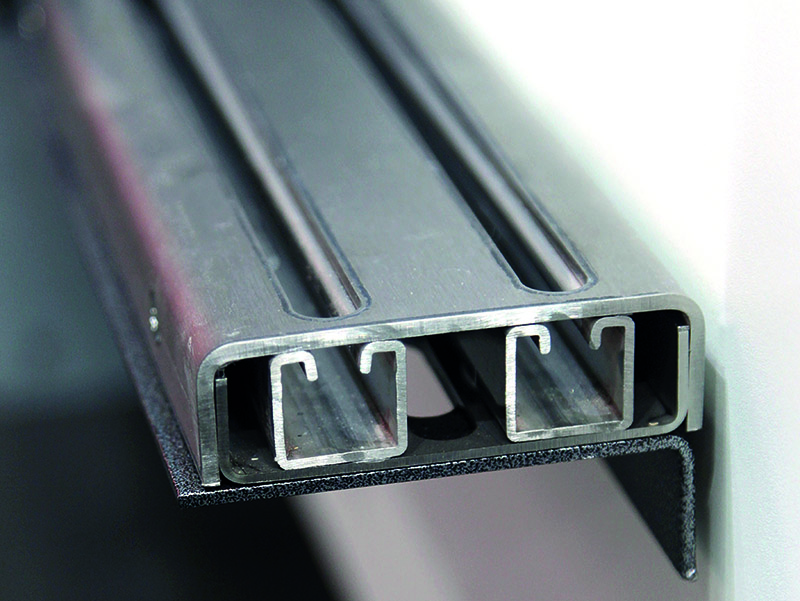

Depending on the desired design, the interior of the threshold body is likewise made of galvanised steel or stainless steel profiles, which are made by roll profiling (also called roll forming or -profiling). Roll profiling is a cold rolling process in which a steel strip is pulled directly from the coil through the profiling plant and shaped step-by-step by several mills and rollers arranged behind each other until the desired form has been achieved at the end of the production process.

Depending on the desired design, the interior of the threshold body is likewise made of galvanised steel or stainless steel profiles, which are made by roll profiling (also called roll forming or -profiling). Roll profiling is a cold rolling process in which a steel strip is pulled directly from the coil through the profiling plant and shaped step-by-step by several mills and rollers arranged behind each other until the desired form has been achieved at the end of the production process.

With this method all kinds of profile cross-sections can be produced continuously and in high quality, precision and strength. In the inside of the Gravida there are such rolled profiles with different cross-sections both as guide profiles for the guidance of the door leaves as well as reinforcement profiles, which endow the threshold with a strength of up to 1.8 tons wheel load.

The combination of the specially formed guide profiles with continuously adjustable door leave guides and sturdy double-walled door leaves guarantee great safety. Doors fitted with the new threshold concept meet the requirements of the new EN 81-20/50. In addition, Gravida® is also a safe and sturdy solution for special applications such as Meiller ScooterGuard (lift doors that withstand the impact of an electric scooter with a maximum weight of 220 kg and a maximum speed of 8 km/h).

All internal guide and reinforcement profiles are full-surface glued with each other and the base and cover plate. Additional screw connections guarantee safe connection of base and cover plate and endow the threshold body with additional strength. Gravida® is suitable for lifts with an ultimate load of up to six tons.da

It also has advantages with regard to the corrosion protection: in these lifts thresholds made of black sheet metal are often used, which have to be grounded retrospectively to protect against rust. This always involves a risk, because retrospective grounding in particular does not reach problem areas such as the insides of profiles or the connecting points of joined parts, or not completely, and consequently does not provide any complete rust protection. Consequently, corrosion is guaranteed. Gravida by contrast is designed to ensure it does not require retrospective rust protection.

The height of the threshold is 28 mm and as a result is identical with the standard aluminium thresholds. As with the latter, the body is screwed onto the threshold substructure, which is mounted on the shaft wall. As a result, the installation as well as the replacement of defective thresholds can be carried out quickly and effortlessly.

Write a comment