Photo: © Kone

News | April 2024

Kone acquires Paca Ascenseurs

Assa Abloy has sold its lift maintenance business Paca ascenseur (Paca) in France to Kone. With this acquisition, Kone intends to strengthen its local presence in the region.

Lift-Staus-Transmitter LST-VOC. (Photo: © BK-Factory)

September 2017

BlueKit, made by BK-Factory, provides solutions for lift shafts, stairwells, technology shafts, smoke pressure systems or technology rooms, which have to be monitored for smoke and ventilated.

BK-Factory is specialised in the technical and normative challenges the building industry must face in the context of the energy transition in the fields of energy, ventilation, smoke venting and conveyance technology.

The days when all that counted in the lift shaft was reliable smoke detection and venting are long gone. As a result of consideration being given to increasingly airtight buildings in EN 81-20, the efficient ventilation of lift shafts – not just on safety grounds, but also to improve the air quality at and in the car – has moved to the fore.

The informative Annex E3 in EN 81-20 points out that people’s safety and comfort in the lift car must be taken into consideration when planning lifts. These depend on several factors, such as air quality, fresh air supply, concentration of CO2 and volatile organic compounds (VOC). This imposes a multitude of tasks on a holistic system that does justice to these demands.

In this respect, BK-Factory has established itself as a pioneer and innovator with its BlueKit systems. The lift status transmitter, connected wirelessly to the car, ensures continuous air quality control to guarantee the safety- and malfunction-related ventilation of the lift shaft and car.

In this respect, BK-Factory has established itself as a pioneer and innovator with its BlueKit systems. The lift status transmitter, connected wirelessly to the car, ensures continuous air quality control to guarantee the safety- and malfunction-related ventilation of the lift shaft and car.

The LST-VOC is not only able to determine the CO2 concentration directly at the car, but also detects volatile organic substances. The LST-VOC recognises all ventilation requirements and institutes natural or if necessary mechanical ventilation at an early stage.

The supply of fresh air is the most important factor in guaranteeing the safety of people trapped in a breakdown. Real-time experiments supervised by TUEV and Dekra have confirmed that in the event of a lift malfunction with people trapped, a low O2 level in the air is to be expected after only 10 minutes and as a result a life-threatening situation for passengers. The tolerance time increases with natural ventilation, meaning grave physical harm can be prevented.

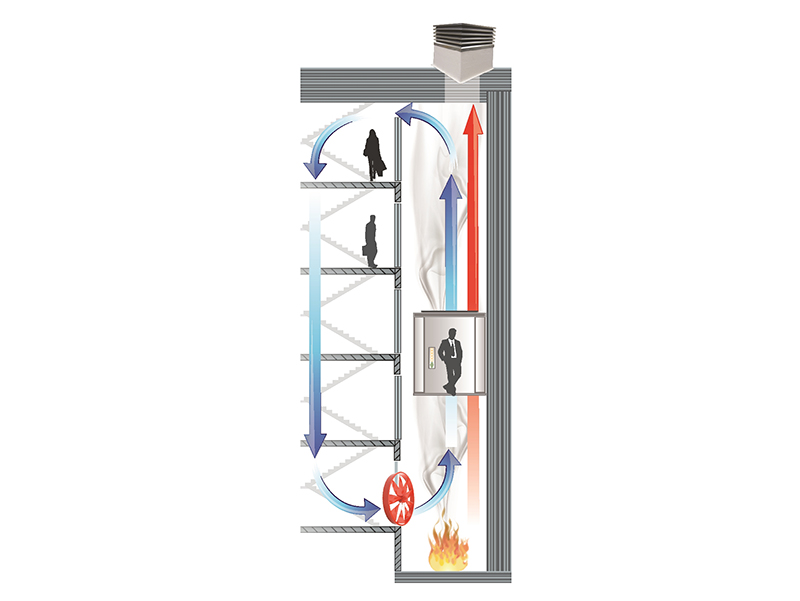

Despite references to the ventilation problem in EN 81-20, lift shafts are repeatedly commissioned with an opening to the stairwell instead of outdoors. As a result, natural ventilation or smoke venting may not occur due to the lack of thermal convection.

BK-Factory also recognised this problem at an early stage and developed a system for mechanical ventilation in the shaft in the form of Lift Vent. The ventilator installed at the bottom of the shaft wall takes care of the upwash required if necessary and in this way aids ventilation or smoke dissipation during the evacuation trip of the lift car.

Moreover, BK-Factory is the only supplier to rely on comprehensively tested fail-safe systems and not, as customary on the market, on the frequently opaque composition of individual components. Caution is required, because fail-safe does not always mean fail-safe! How does the system react, for example, if the connecting cable is damaged by third parties or how does it process a short-circuit in the fire alarm line? The BlueKit L-CT systems developed by BK-Factory were therefore examined as an overall concept by the test centre Kriwan and their full functionality confirmed.

Moreover, BK-Factory is the only supplier to rely on comprehensively tested fail-safe systems and not, as customary on the market, on the frequently opaque composition of individual components. Caution is required, because fail-safe does not always mean fail-safe! How does the system react, for example, if the connecting cable is damaged by third parties or how does it process a short-circuit in the fire alarm line? The BlueKit L-CT systems developed by BK-Factory were therefore examined as an overall concept by the test centre Kriwan and their full functionality confirmed.

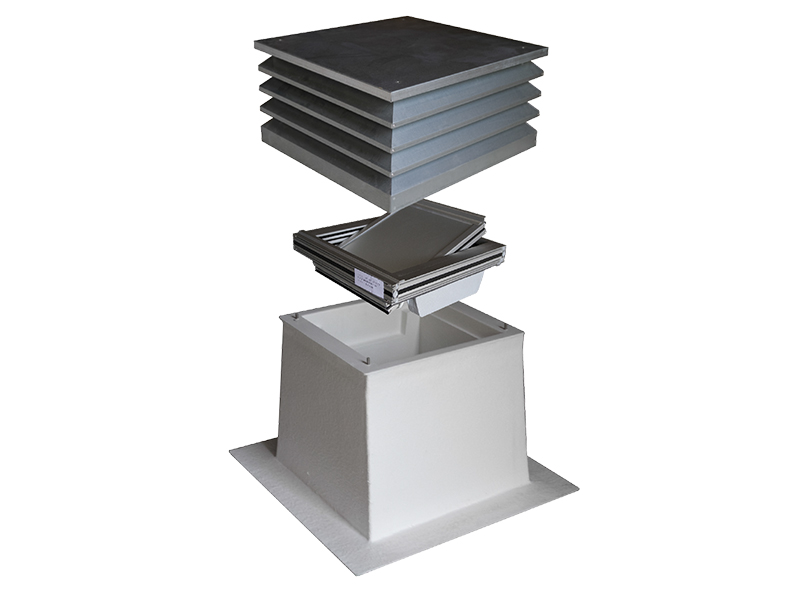

Just how important the examination of a system compared to individual components can be is evident at the latest upon inspecting the declared measured values in the area of the natural smoke and heat venting devices. The patented Thermo Flap, consisting of curb, closure element and weather protection and ribbed cover has an excellent documented U-value of 0.41 – 0.55 W/m²k for the entire ventilation element.

Comparable natural smoke and heat venting devices on the market only refer to the U-values of the components without taking the heat bridges between these components into consideration when calculating the actual U-value of the entire device. BK-Factory’s Thermo Flap has naturally also been tested as a structural component according to 12101-9 and - as legally required - the entire unit has been certified as a natural smoke and heat venting device.

Write a comment