Photo: © Kone

News | April 2024

Kone acquires Paca Ascenseurs

Assa Abloy has sold its lift maintenance business Paca ascenseur (Paca) in France to Kone. With this acquisition, Kone intends to strengthen its local presence in the region.

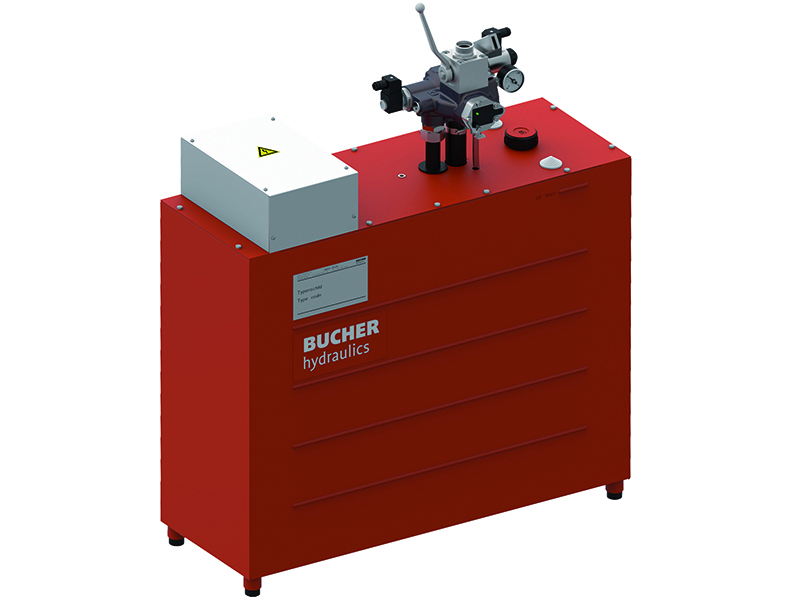

The intelligent valves of Bucher Hydraulics’ iValve series have set new standards in lift hydraulics. Fitted with the CANopen-Lift interface, all of the information relevant to operation, such as parameters and status data, are retrievable via the lift controller. (Photo: © Bucher Hydraulics)

October 2019

By interconnecting the intelligent iValve and CANopen-Lift, Bucher Hydraulics is making new ways of starting up and maintaining lifts possible.

Digitalisation and networking offer completely new options for modern lift hydraulics. Bucher Hydraulics aims to break new ground here for innovative solutions. It is constantly developing its valve technology in combination with sensor systems and bus technology.

The intelligent iValve with CANopen-Lift interface provides the basis for far-reaching potential in developing hydraulic lifts. This potential is already available for use during the time-and cost-saving installation and start-up. In addition, thanks to remote monitoring and the associated predictive maintenance, lift manufacturers are in a position to develop new maintenance concepts.

"Better to get started right now than wait for the complete impending industrial revolution," is the underlying idea when it comes to new technologies for hydraulic lifts. If such a system, one that has been reliable for decades, is now to undergo further development to adapt to future changes, this is best done step-by-step. The prime target is not "Industry 4.0" but rather making work easier, as in shorter start-ups and faster data access, which derive from networking and the implementation of digital technologies.

However, the precondition for all of this is selecting the right basic components to ensure that every path for later modifications or extensions remains open. "As a specialist and pioneer in developing hydraulic lift components, Bucher Hydraulics is exploiting both its decades of product know-how as well as far-reaching industry insights to show lift manufacturers valuable potential ways to boost efficiency," the company stated.

However, the precondition for all of this is selecting the right basic components to ensure that every path for later modifications or extensions remains open. "As a specialist and pioneer in developing hydraulic lift components, Bucher Hydraulics is exploiting both its decades of product know-how as well as far-reaching industry insights to show lift manufacturers valuable potential ways to boost efficiency," the company stated.

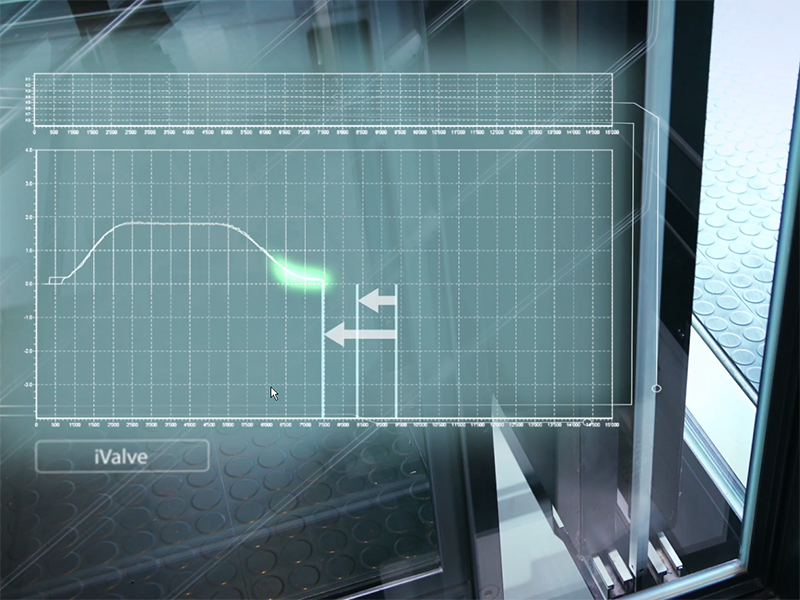

Based on this background knowledge, great store was already set on economic efficiency and potential uses at the very beginning of the development and design of iValve. The intelligent valve operates with a specific learning algorithm, which integrates basic settings and current travel data and optimises them. This intrinsic intelligence ensures the car starts faster and that the landing can be directly approached. This shortens travel times and enhances energy efficiency.

The integrated electronics cover all of the parameters for setting speed, acceleration and related factors. Up to now, lift technicians could alter these values in the lift on the spot with a handheld terminal. However, this means that specific handheld terminals not only have to be available for components like the drive, controller or doors, but also for making changes on the spot, which in turn results in additional costs.

You also have to know how to use the handheld terminals. For this reason, Bucher Hydraulics has now taken a further important step and according to the company is the first manufacturer for lift hydraulics to use the CANopen-Lift interface as a forward-looking connection for an intelligent valve with standard controllers.

Together with the valve function iAccess and built-in sensors for pressure and temperature measurement, the iValve can now also communicate directly with the controller. This makes it possible to transmit travel commands fast as well as to display operating data, status- and error messages or alter valve parameters on the controller.

According to Bucher Hydraulics, this technology offers several advantages at once: during installation and start-up, the reduced wiring work saves time and simultaneously reduces potential error sources. In addition, an error memory saves all the relevant information that can help in taking well-founded lift troubleshooting decisions.

According to Bucher Hydraulics, this technology offers several advantages at once: during installation and start-up, the reduced wiring work saves time and simultaneously reduces potential error sources. In addition, an error memory saves all the relevant information that can help in taking well-founded lift troubleshooting decisions.

Depending on the controller, the data can be displayed in different formats. The spectrum ranges from a two-line display on a TFT screen and touch screen to a smartphone app via Bluetooth and is undergoing constant further development. Consequently, users get uncompromising insight into the system without the need for additional equipment and can intervene quickly using the controller installed.

The diagnosis functions that are transmitted via bus systems are the basis for forward-looking maintenance and demand-actuated maintenance. They are designed to increase lift availability. The early planning of foreseeable measures is intended to save time, travel and costs, since potential errors can be identified before any standstill.

Combined with CANopen-Lift, lift manufacturers can deploy the valve technology of the iValve according to individual requirements for the hydraulic lift and configure it for future customer wishes. Further steps will allow lifts to be increasingly networked and digitalised and as a result made more intelligent. This naturally also applies to modernisations of existing hydraulic lifts.

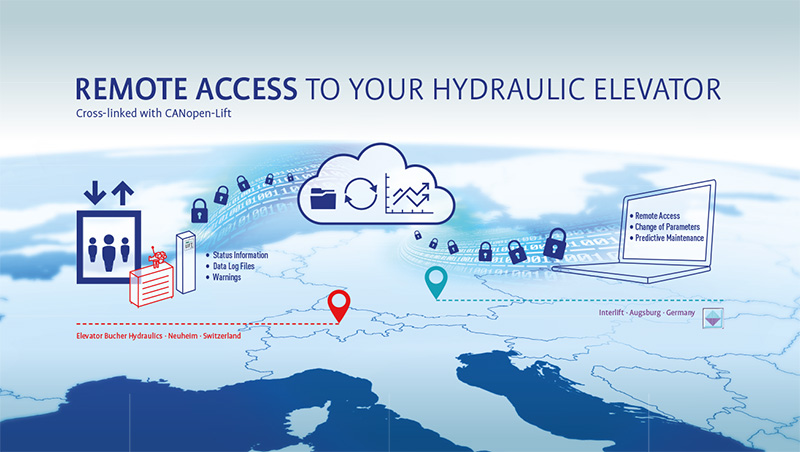

The spectrum ranges from the implementation of the intelligent valve together with the standardised interface to complete networking of the lift components via the Internet. The data can also be monitored and retrieved remotely on a central computer in a control room. Fast access is guaranteed in this way, for example, in very busy public buildings, such as railway stations or shopping centres. Internet connections can be individually restricted by selective access rights as protection against cyber-attacks.

In the era of the ‘Internet of Things’, prospective maintenance solutions are the new core competence. Despite different development levels of such prospective maintenance solutions, the objective is always the same: avoiding costly standstills, more effective distribution of maintenance solutions and more economic planning of maintenance activities.

In the era of the ‘Internet of Things’, prospective maintenance solutions are the new core competence. Despite different development levels of such prospective maintenance solutions, the objective is always the same: avoiding costly standstills, more effective distribution of maintenance solutions and more economic planning of maintenance activities.

Thanks to real time digital monitoring, components are no longer repaired or replaced unnecessarily, simply because of prescribed intervals. Instead, the actual need for repairs can be recognised in time even without on the spot inspection, rendering the previously needed inspection trips unnecessary and permitting deployment plans to be optimised.

To sum up, digitalisation and networking are thus not only changing the manufacture of lifts, but also their start-up and the entire service process, where reliable and life-extending maintenance measures are key factors.

Today, successfully defending market position or achieving company growth already demand greater distribution areas for lift manufacturers and as a result travelling further. By integrating new technologies into the business model, far better care of these larger areas is possible, since service personnel can be deployed more efficiently due to prompt information.

To meet all these challenges and press the strategic ‘up’ button on "Lift 4.0" in good time, the intelligent iValve from Bucher Hydraulics is ready to offer the necessary preconditions for this today.

bucherhydraulics.com

Hübschmann: lifts with integrated future technology

Write a comment