Photo: © helinntonfantin/123RF.com

News | April 2024

The Spaniards are coming

Do the Big 4 have to get ready for expansion? A company transaction largely unnoticed by the public now points to this.

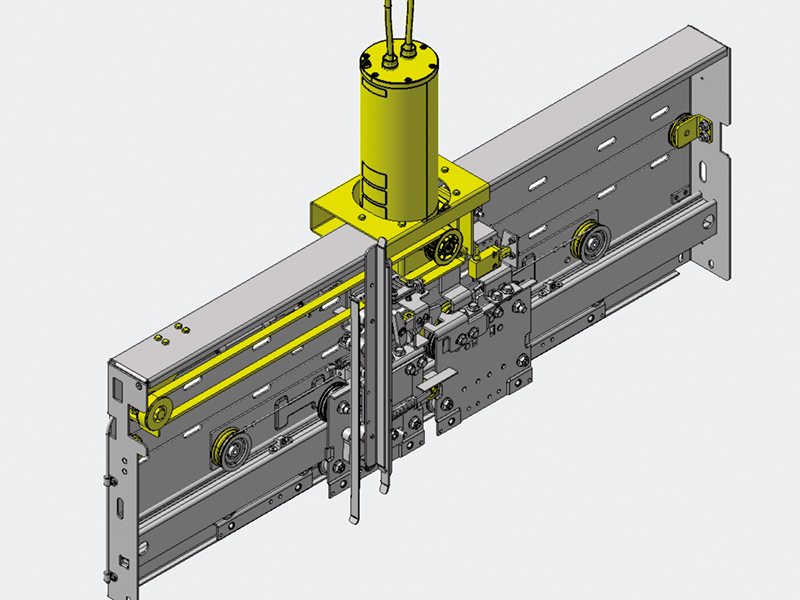

(Photo: © Meiller Aufzugtüren GmbH)

September 2018

A new legal framework entered into effect for the new regulation of explosion protection in Europe on 20 April 2016 in the form of the ATEX Directive 2016/34/EU.

The previously applicable Directive 94/9/EC became invalid with the entry into force of its successor. Meiller has now adjusted its current product line accordingly and can provide solutions for explosion zones 2/22 and 1/21.

Depending on the design, these doors can be used in explosive atmospheres of the groups IIA-IIC and IIIA-IIIC, for temperatures between T4 and T6 or for operation in highly sensitive gas atmospheres, such as carbon disulphide, carbon monoxide and ethylene oxide.

Based on EN 81-20 and EN 81-50 in combination with the ATEX Directive 2016/34/EU, the door product range includes the TG3 horizontal sliding door product family, TTS/K25 two-leaf telescopic doors, STS/K26 two-leaf centrally-opening doors, TTS/K28 four-leaf centrally-opening doors, TTS/K31 three-leaf telescopic doors and TTS/K32 six-leaf centrally-opening doors.

Landing doors are available both in "EvoS" shaft wall installation as well as in "EvoN" niche installation. Sizes extend up to a door width of 4200 mm and a door height of 4500 mm with a maximum driven mass of 600 kg.

The ATEX concept is based on the tried-and-tested TG3 basic concept, with a landing door impost height of 347 mm and car door impost height of 470 mm. The goal here was to standardise mechanical wearing parts, use all proven catch systems in the TM1 series and be able to select hinged doors.

Provision is made for double-catch systems for four- and six-leaf doors; consequently, doors for extreme loading in HD design are available. Emergency unlocking in designs with mono-stable monitoring switches are just as feasible as light grid solutions.

Doors can be made either out of zinc magnesium sheet metal or completely from VA. Additional surface finishing on the visible side is possible for doors in zinc magnesium design.

Doors can be made either out of zinc magnesium sheet metal or completely from VA. Additional surface finishing on the visible side is possible for doors in zinc magnesium design.

Thanks to the use of the proven TG 3 technology, the handling and adjustment of the ATEX doors are almost identical with those of the standard design, apart from the additional earthing measures. Most fitters are already familiar with the product as a result of the identical assembly and adjustment principle in water- and explosion-protected doors.

These doors use the new drive concept MiDrive. The MiDrive EX can be operated just as intuitively as the MiDrive units already presented at interlift 2017. Start-up is easy and performed by QR code. As a result, additional safety-relevant parameters are restricted to be more user-friendly and block or prevent borderline, improper settings (such as dangerous releases of the cogged belt at excessive belt speeds).

The travel profile is adjusted automatically at increased temperatures; this reduces the power consumption and heat development and the drive can cool down again correspondingly, thus increasing the availability of the system.

The control of the drive motor is integrated in the motor The controller and transformer must be located outside of the explosion zone (e.g. in the machine-room); line lengths of up to 100 m can be realised to the explosion motor.

Thanks to the selection of the drive control with CANopen, the new ATEX from Meiller is highly resistant to malfunctions. Moreover, the MiDrive EX supports observance of the ATEX-specific maintenance intervals with appropriate reminders.

The new Meiller ATEX sliding door product range has been available since the end of 2017; this will be followed in the middle of 2018 in this protection class range by the Premius vertical door range as car separation door K4i and as landing separation door S4i. The repair kits MAT-EX for MiDrive-EX will likewise soon be available.

Write a comment